Elite Meat

Packing

Tech

About Elite Meat

Elite Meat Packaging Tech’s novel packaging films for fresh meat packaging are designed to allow a small amount of oxygen to pass through the film, thus maintaining the oxymyoglobin that gives meat its fresh red color. Thus, meat cuts wrapped in plastic film at the market can be safely stored.

Vision

Mission

Process

Packed

In Stores

Meat is one of the most perishable foods!

Problems We Work On

- Global meat production: 300 M tons.

- Annual loss: ~20%.

- That’s 60 M tons!

- Most of this meat is not bad to eat!

- Most loss is due to sensory qualities:

- Changes in texture

- Color deteriorations

- Off-odors

Meat Spoilage Mechanisms

1) Natural lipid oxidation

2) Autolytic enzymatic reactions

3) Bacterial contamination

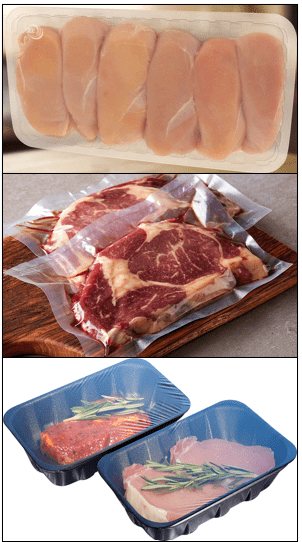

Current Packaging Methods

- Overwrap Packaging

- Cost-effective

- Short shelf life

- High exposure to O2

- Vacuum Packaging

- Protects colour & flavour

- Effective short-term use

- No protection against anaerobic bacteria

- MAP – Modified Atmosphere Packaging

- Vacuum sealed in vapour-barrier

- Mixture of O2, N2, CO2

- Removes/replaces atmosphere around the product

- Prolonged shelf life

- Higher expense

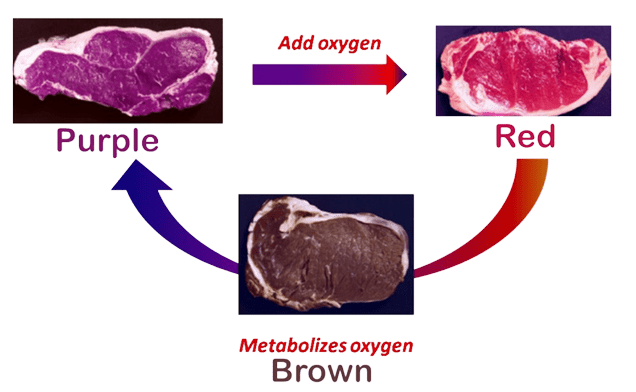

Colour is the Single Biggest Decision-making Parameter for Consumers When Selecting Meat

- Meat colour depends on oxygen + myoglobin

- MAP allows oxygen to pass through giving the desirable red colour

- BUT continued oxygen exposure + store lighting eventually turns the meat brown

OUR SOLUTION

18-inch Film Wrap Stand-alone or for MAP

Sold by Roll Dimensions: 18 in x 5000 ft Weight: 34 lbs

- Can double the shelf life of red meat

- Roughly twice as effective as other existing packaging solutions

- Cost-effective by avoiding multi-layered approach to packaging

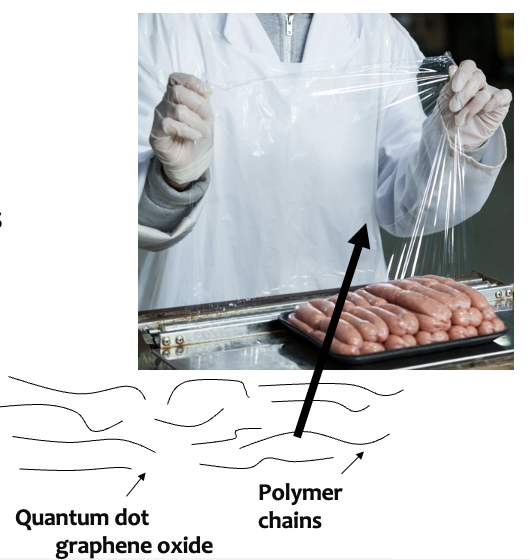

Elite Meat is also seeking to be one of the first packaging companies to manufacture and distribute Quantum Dot and MAP. Technology within Canada

Product:

Elite Meat MAP Using Quantum Dot Film

Gives best results

- Quantum dot film

- Standard polymer tray

- Modified atmosphere (high/low oxygen)

Production Progress

1) Mix the quantum dot graphene oxide nanoparticles (15-30 nm) with the polymers

2) Produce the modified packaging film from the blown film extruder

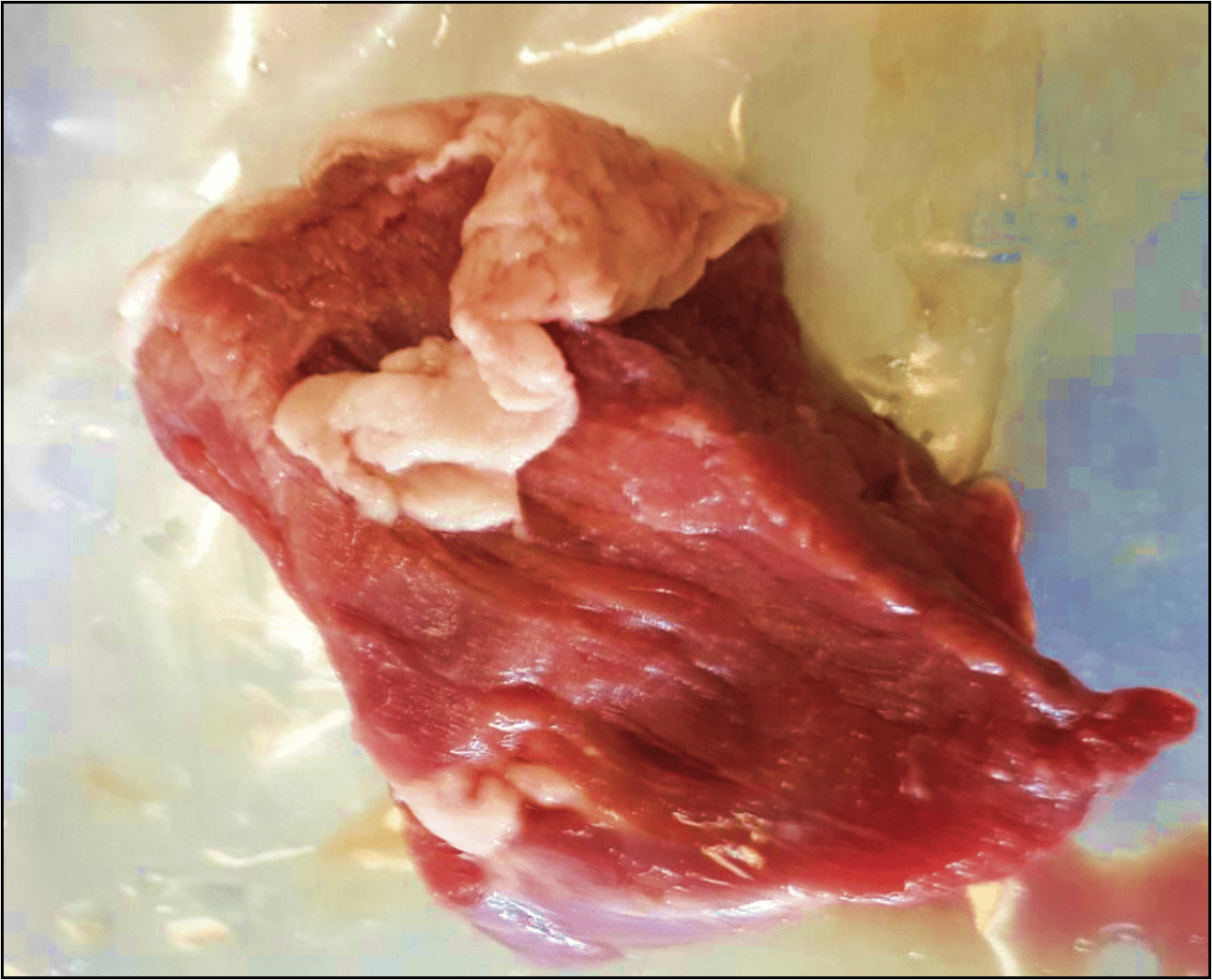

LAB RESULTS

Red Meat Packaged by Elite Meat Packaging Tech at Day 12

Red Meat Packaged by Commercial Plastics at Day 12

Our Satisfied Customers

Our Team

Olufemi Akinwunmi

CEO

Andy Ogbeide Ikponmwoba

CTO

Osasumwen Isibor

CCO

Our Blogs

Rising Demand for Customized and Convenient Fresh Meat Packaging in North America

The North American fresh meat packaging market is experiencing significant growth, projected to reach approximately USD 1,070.9 million by 2033, expanding at a CAGR of about 3.7%.

Global Fresh Meat Packaging Market: Driving Innovation for Quality and Sustainability

With the global demand for fresh meat packaging projected to grow by $2.48 billion between 2020 and 2025, the industry is set to transform significantly.

Redefining Meat Packaging with Quality, Innovation, and Sustainability

As global demand for high-quality meat continues to rise, so does the need for innovative packaging solutions that can keep up.

Transforming Meat Packaging with Nanocomposite Films

As global food needs escalate, Elite Meat Packaging Tech is pushing the boundaries of food preservation with our cutting-edge nanocomposite film, combining the power of quantum dot graphene oxide (GO) technology and robust polymers.

Elite Meat Packaging Tech’s New High-Performance Film Wrap

As global food demand intensifies, Elite Meat Packaging Tech is leading the way with our newest innovation: a high-performance, cost-effective packaging film designed specifically for meat products.

How Elite Meat Packaging Tech Supports a Changing Global Diet

As we look toward 2050, with global population growth expected to reach 9.5 billion, the world faces significant shifts in food demand and consumption patterns.

Contact Us

Location

205, 10211 Yonge Street, Richmond Hill, ON, Canada L4C 3B3

info@elite-meat.ca